How To Set Timing On Chevy 350

Dropping a distributor into the engine is a fourth dimension-honored process that has been around since the first engines coughed their way to life more than 100 years ago.

With the latest generation of distributor-less engines, this tribal cognition has slipped from its "must-know" status. But if you are working on an older engine with a benefactor, this is essential information.

The process is easy and information technology will take longer to read near than to actually perform the task, then let's get started.

For this procedure, we volition use a modest-block Chevy considering that was the closest engine for the photos. However, the process we'll describe is exactly the same for any four-stroke engine.

Our item engine is a make new Chevrolet Goodwrench crate engine on which we've already installed a new intake manifold.

In our instance, the spark plugs were all removed, which makes turning the engine over very piece of cake. If the engine is in the car, you can use the starter motor to crank the engine.

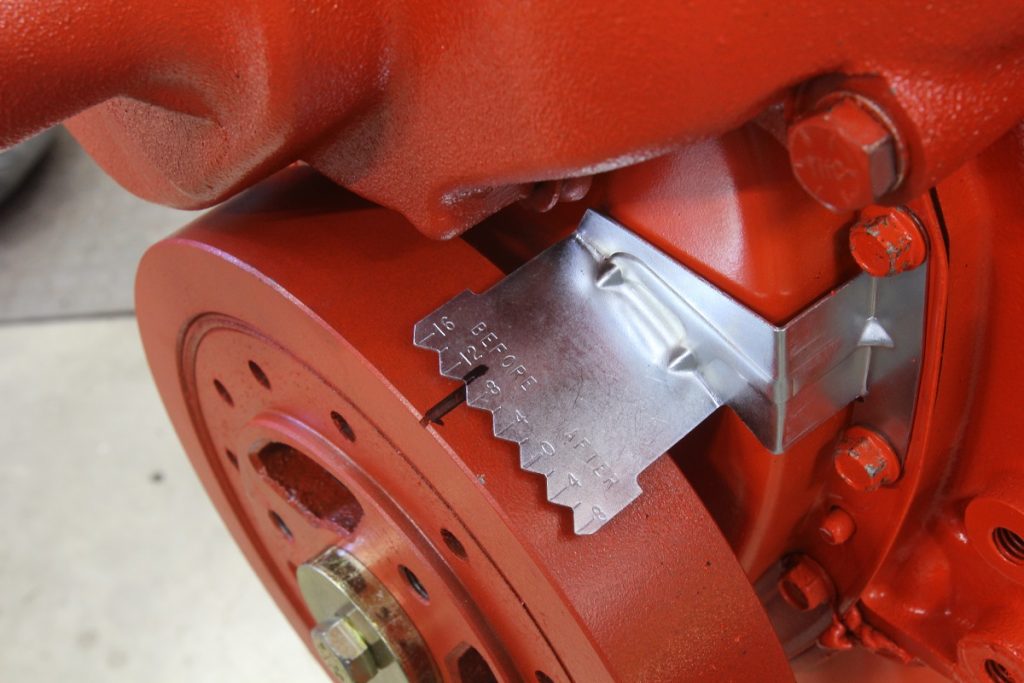

With the Number One spark plug removed, place your thumb over the pigsty while turning the engine. Once you lot feel compression edifice, look for the zip marking on the harmonic balancer to approach the timing tag. We prefer to set the initial timing for most engines at x degrees Before Top Expressionless Center (BTDC).

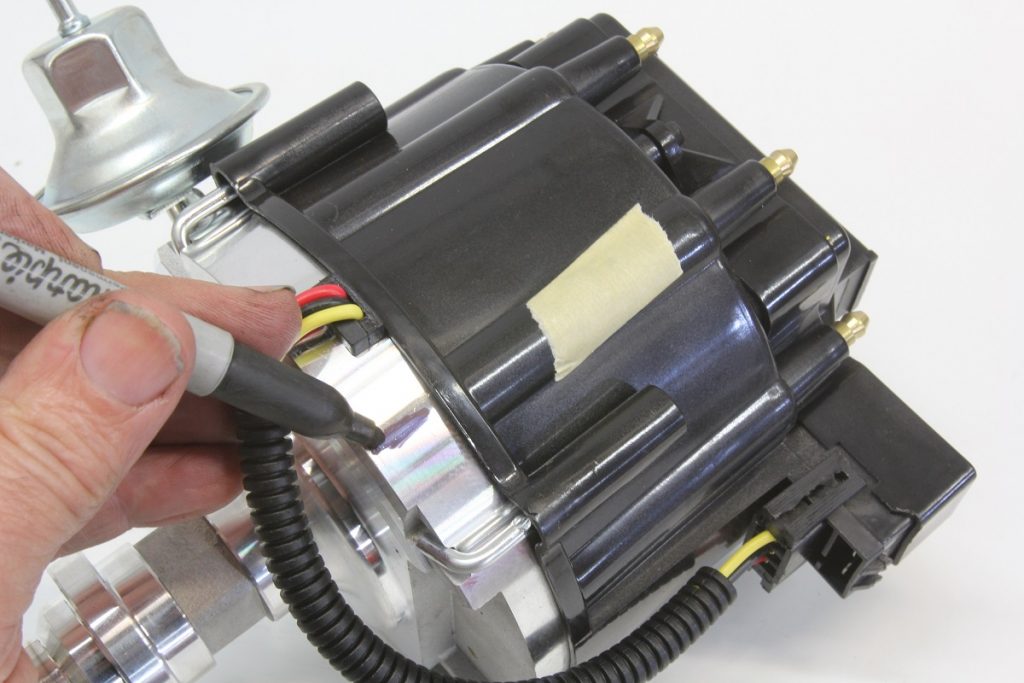

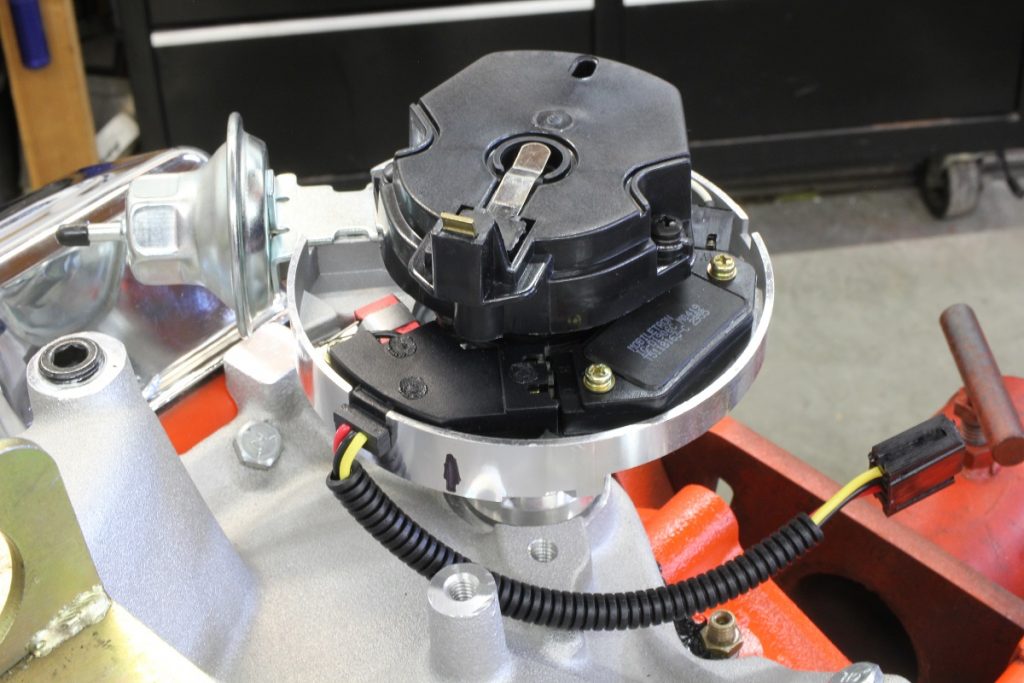

With that prepare, remove the cap from the distributor. Nosotros're using a Summit HEI benefactor. Nosotros use a blackness Sharpie to identify a marker on the benefactor body where nosotros desire the Number 1 spark plug wire to be located. This tin can be placed anywhere yous similar, simply if you are a Chevrolet traditionalist, this ends up roughly at nigh the five o'clock position on the distributor as you are looking at it from the front of the engine.

Also place a mark on the respective Number One plug wire position on the distributor cap. We used a piece of masking record.

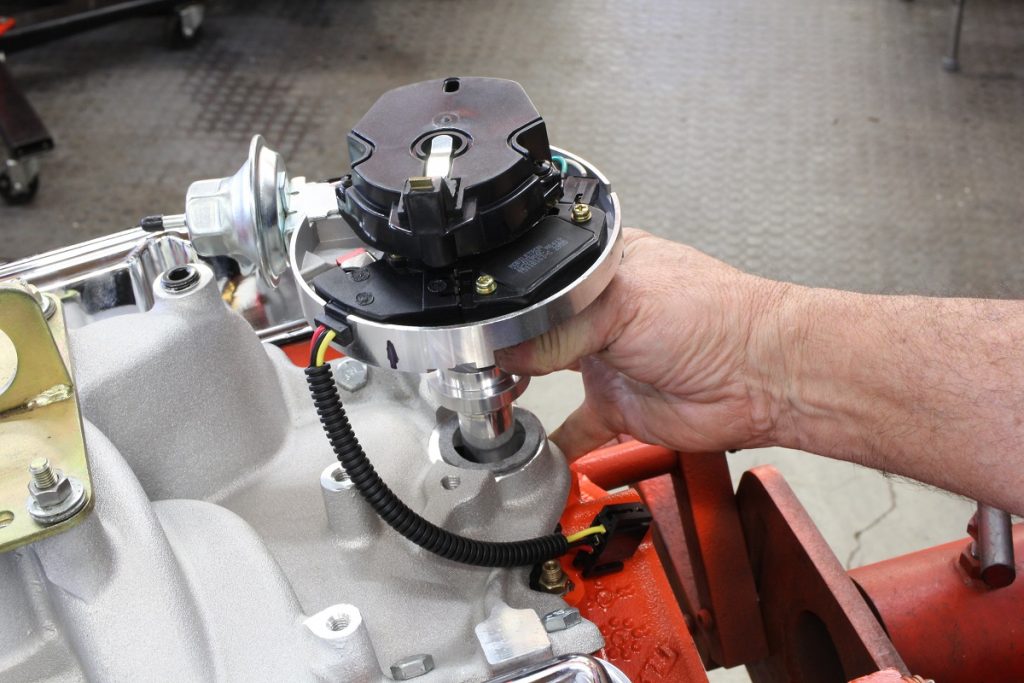

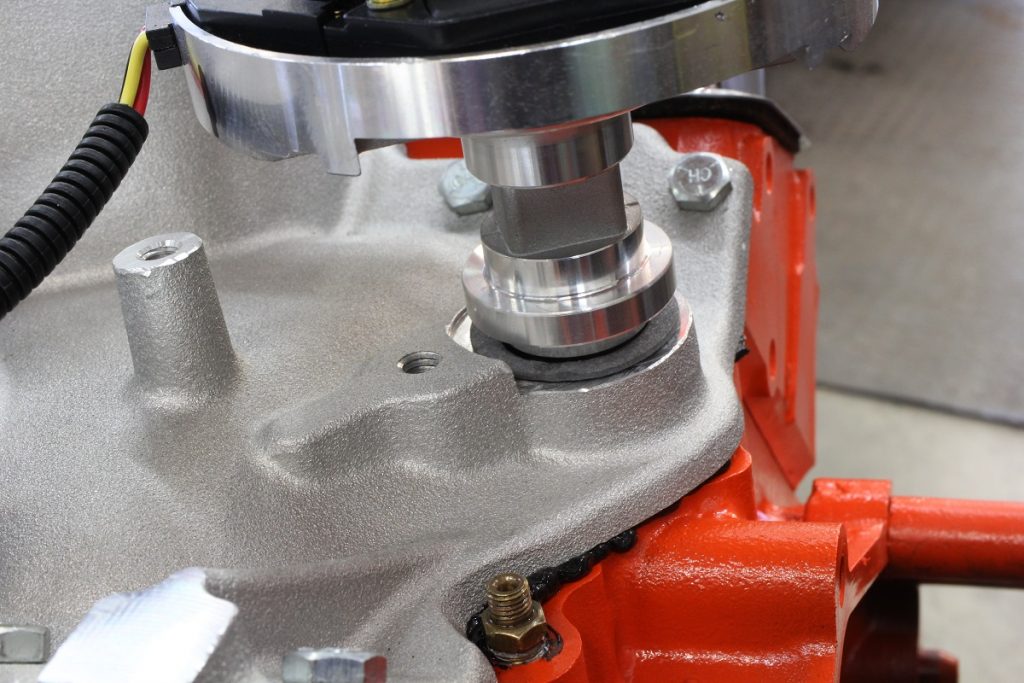

With these marks in place, drop the distributor with the gasket into the distributor hole with the rotor pointing nigh the Number One mark.

Equally the distributor drive gear engages the teeth on the camshaft, this will move the rotor slightly clockwise. Position the benefactor and so that the vacuum advance canister is located on the rider side of the engine pointing roughly forrad. If the rotor is non pointed close to the Number One mark, pull the distributor and re-position the rotor until information technology comes shut.

Unless you are very lucky, the distributor volition not drop fully into the intake manifold. In nigh all cases, the distributor will sit down near 3/viii inch off of the manifold. This is normal and is caused by the oil pump drive not engaged into the drive tang in the distributor. You can remove the distributor and try to re-orient the oil pump bulldoze slot with a long straight screwdriver, but this is somewhat difficult.

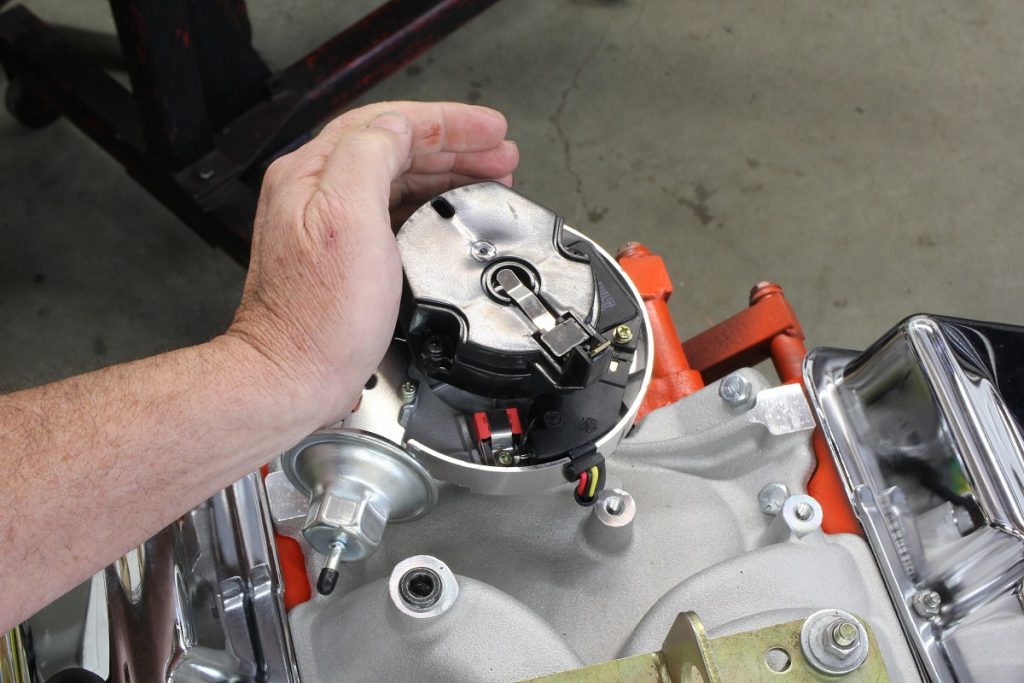

It'south easier to get out the distributor in place and then crash-land the engine with the starter motor while placing very lite downwardly force per unit area on the distributor body. Subsequently a one-half rotation or and then, the distributor will driblet in identify. Now we will need to creepo the engine until again it is located at 10 degrees BTDC. With this accomplished, check to ensure the rotor is pointed most the mark on the distributor trunk for Number One spark plug wire. If the rotor is not pointing at Number One, you could twist the distributor body, but if it is off by more one tooth, this will crave turning the distributor trunk also far. Instead, you volition need to remove the distributor and echo the previous process as the rotor is non in the correct position.

With the rotor close to the Number 1 position, twist the benefactor trunk until the rotor points direct at the Number I spark plug last position mark on the distributor. At present install the distributor cap and cinch the benefactor body downwardly to the intake manifold with the concord-down clamp. Tighten this lightly—we may accept to motility it again when the engine starts.

With the distributor in identify, install all of the spark plugs. Now we can connect the spark plug wires to the distributor.

Let'southward presume that you've never done this before. Before nosotros can place the wires in the distributor cap, the beginning thing we demand to know is which management the rotor turns.

For our Chevrolet engine you lot'll note that the rotor turns clockwise. Small- and big-cake Fords turn counter-clockwise.

…

Tech Tip: One quick way to tell on any vacuum accelerate style distributor is to lay your hand parallel with the vacuum advance canister and then whorl your fingers inwards toward the middle of the distributor body. The direction your fingers indicate is the management of rotor movement. On a Chevy distributor, you lot would utilize your left hand, and on a Ford yous'll use your correct hand. This is a cool little play a joke on you can apply on any distributor to determine its rotation.

…

On small- and large-block Chevy engines, the Number 1 cylinder is always the commuter's side forepart.

Chevrolet also numbers its cylinders with odd numbers on the left (driver) side and fifty-fifty cylinders on the right.

The left side is numbered 1-3-5-vii, and the correct side is two-iv-vi-eight.

Ford does it differently. Ford numbers its cylinders with Number One on the right front, numbered on the right side ane-2-3-4 with the left side 5-6-7-eight. Other manufacturers number their cylinders differently, and then y'all should check online if y'all're not sure.

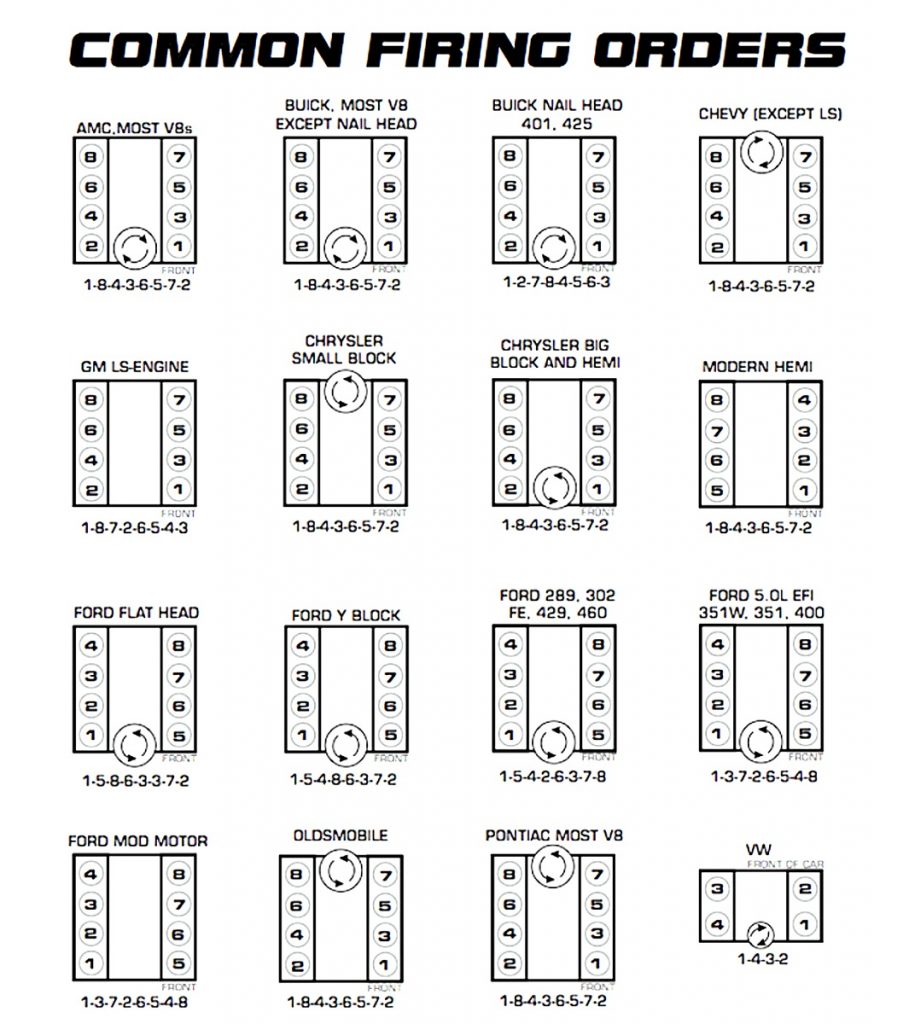

See OnAllCylinders' firing order crook sheet for installing the plug wires in the correct order.

Our small-block Chevy firing order is 1-viii-4-3-half dozen-5-7-2, so that'due south the order in which nosotros will install the plug wires.

Nosotros started with Number 1 and worked our way effectually the distributor cap clockwise using a set up of Superlative spark plug wires. The all-time mode to do this then you don't get confused is to just follow the firing gild installing each plug wire through the order.

Get out a little actress room with the spark plug wires to allow freedom of movement in the distributor. For Chevys, be careful to brand sure 5 and vii are installed correctly. If the wires are accidentally switched, the engine will not be happy.

Before we try to start the engine, be sure the distributor is continued to switched power. With an HEI distributor, there is a three-wire inboard connector betwixt the HEI module and the cap.

On the outboard side of this connector, there are two smaller individual connectors—one for power from the ignition switch (marked BATT) and the other for a tach. With those connections in place and the distributor, plugs, and wires connected, we're almost ready to start the engine.

Connect a timing light to the Number One cylinder. Now we're ready to burn the engine. Assuming the engine starts, brand sure the engine is idling at proper idle speed and not on the fast-idle cam of the choke.

Information technology'due south of import that the engine be idling at its warm-idle rpm. It's likely that our static ignition timing at the crankshaft at idle may not be the desired 10 degrees BTDC.

If it must be changed, just loosen the hold-down nut and arrange the distributor until the initial timing on the crankshaft is at the desired timing figure. Of form, you are gratis at this point to fix the initial timing at its proper spec.

We will save the give-and-take nearly initial, mechanical, and vacuum advance for a subsequent story, just you at present have the distributor set in place and the plug wires installed correctly and it'southward entirely possible that the engine will run much better at present with a properly timed ignition.

Source: https://www.onallcylinders.com/2020/04/16/how-to-install-a-distributor-and-set-initial-timing/

0 Response to "How To Set Timing On Chevy 350"

Post a Comment